- Why smartBuild

- Why Arcadia

- Products

-

-

-

Products

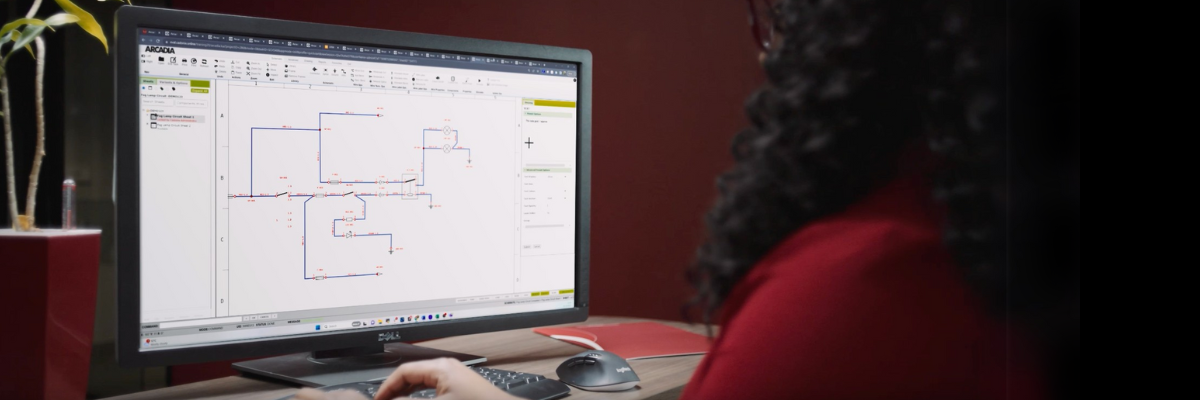

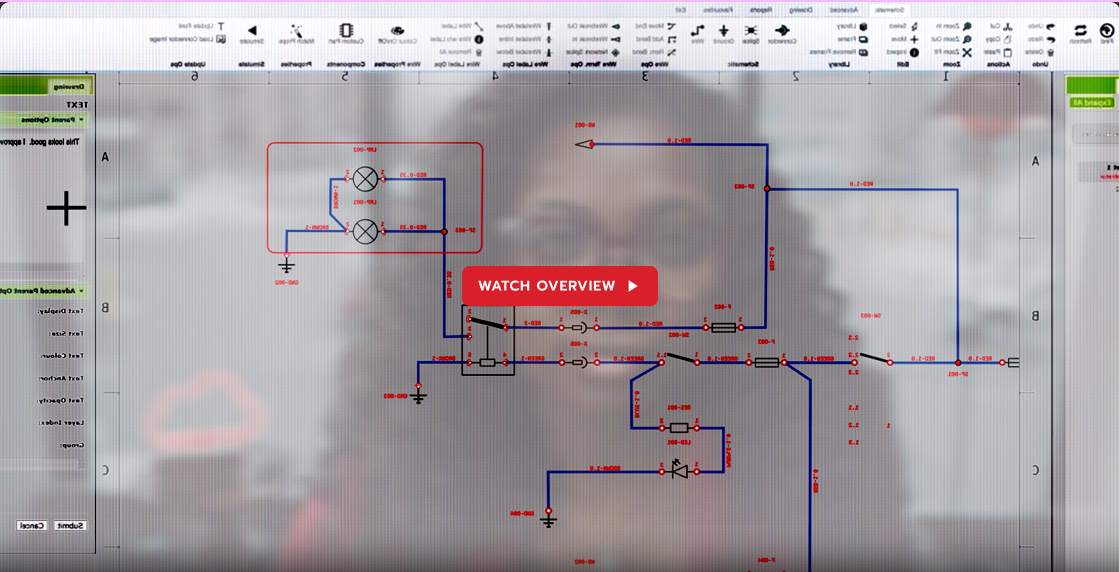

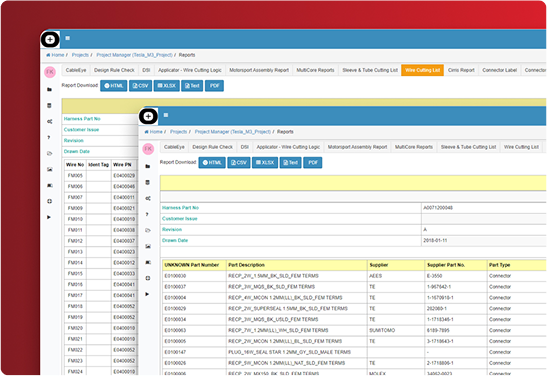

The Only All-In-One Harness Design, Quoting and Manufacturing System

-

-

-

Product Bundles

Perfect For Harness Designers and Manufacturers

-

-

-

Expansions & Integrations

Available Exclusively With The Arcadia Professional License

-

-

-

-

-

- Pricing

- Resources

-

-

Resources

-

-