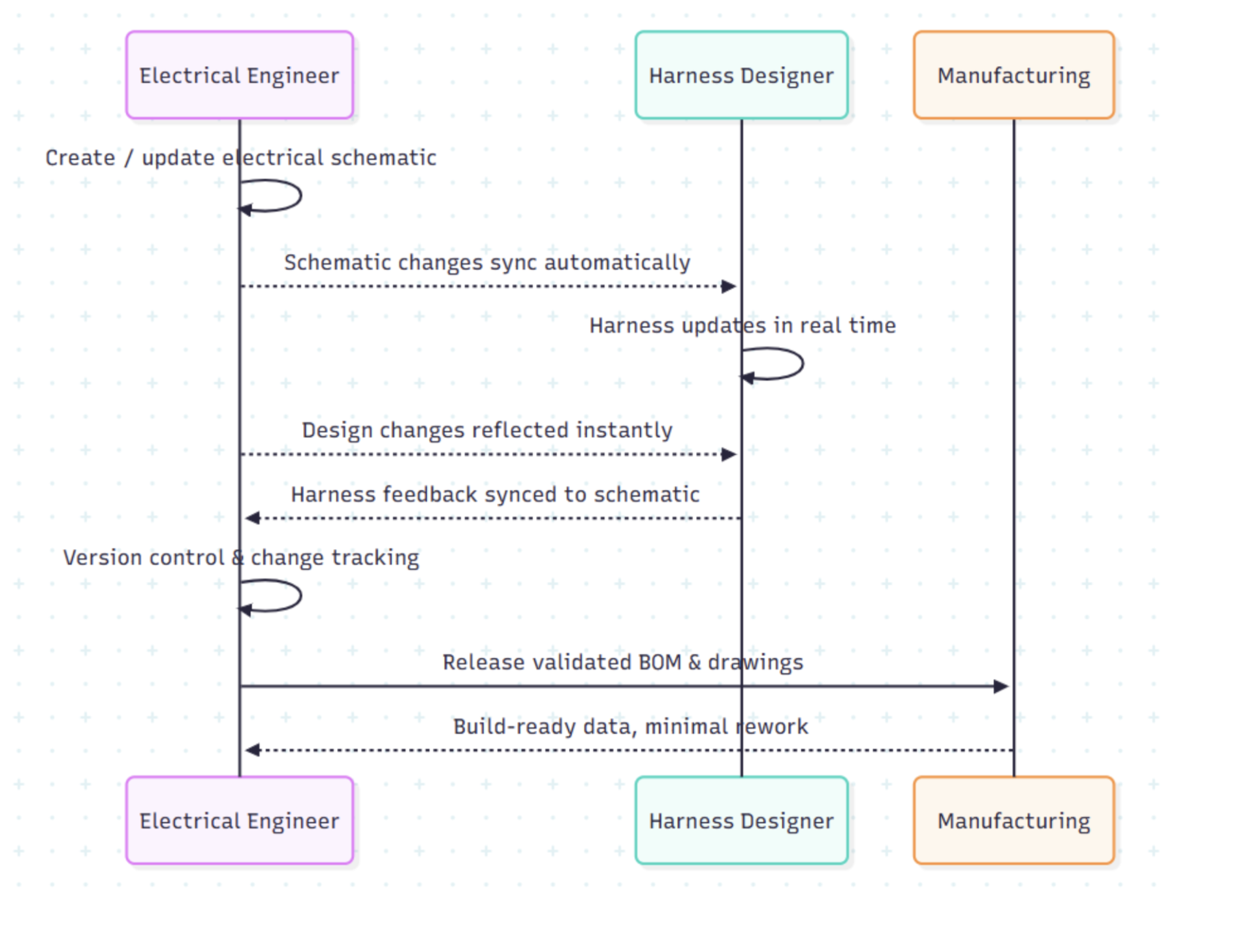

As EV platforms continue to evolve, engineering teams must adopt workflows that scale with complexity rather than fight it. Future-proofing starts with a connected ECAD foundation that supports rapid change, real-time collaboration, and intelligent validation.

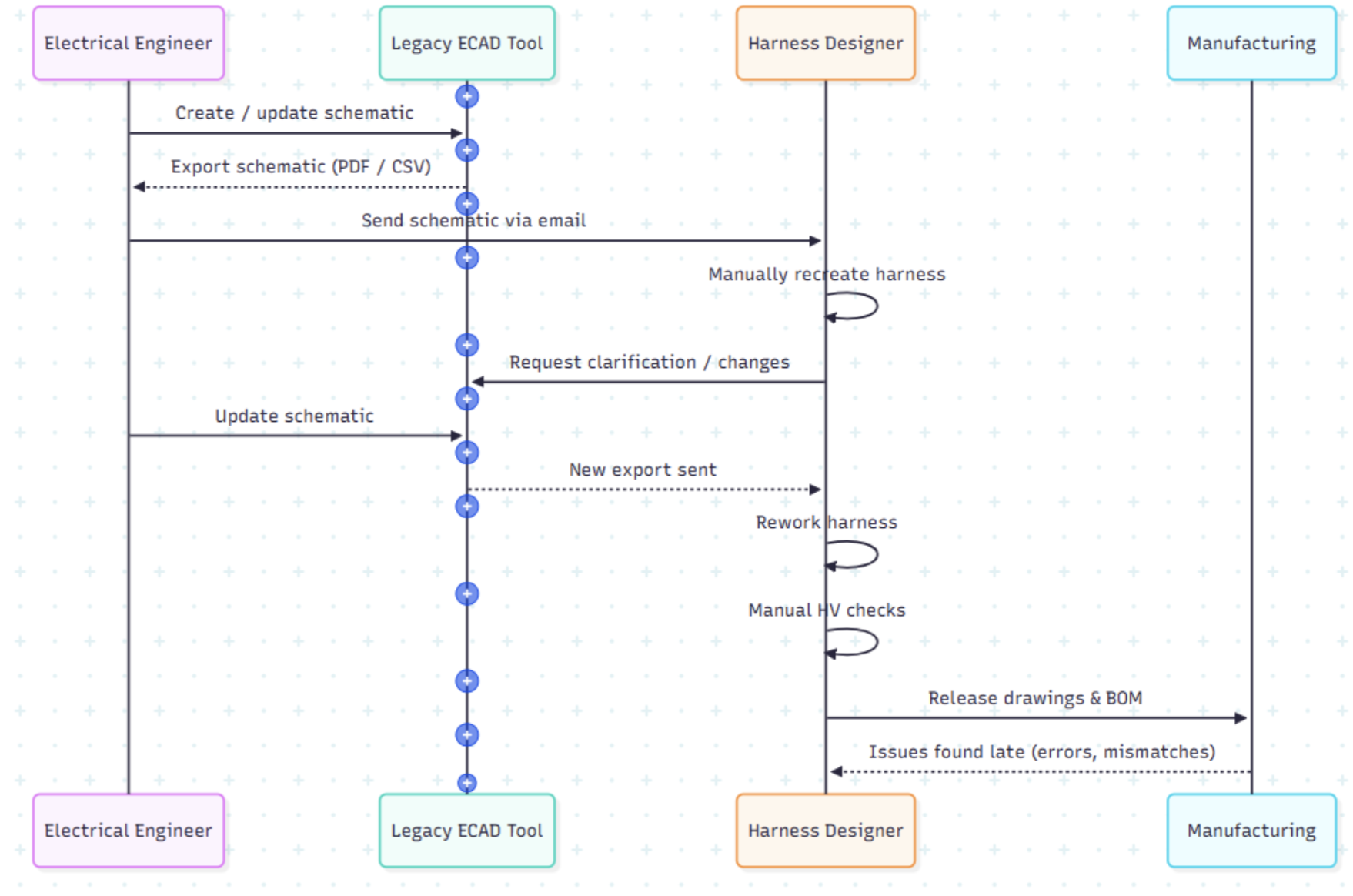

Teams should focus on eliminating manual handoffs, reducing data duplication, and ensuring that every design change flows seamlessly from schematic through harness to manufacturing. With the right ECAD platform in place, EV programs gain the agility they need to adapt without sacrificing quality or safety.

Modern ECAD tools do more than support EV harness design. They enable engineering teams to build safer, smarter vehicles while keeping pace with an industry that never slows down.

Arcadia fits naturally into this shift toward modern ECAD. Built as a cloud-based platform, Arcadia connects electrical schematics, wire harness design, and manufacturing outputs in a single environment. For EV programs, this means high-voltage architectures, safety constraints, and configuration changes stay synchronized across the entire design process. By replacing disconnected workflows with a single source of truth, Arcadia helps engineering teams manage complexity, reduce risk, and deliver EV harness designs with greater speed and confidence.

Ready to design EV harnesses without the risk and rework of legacy tools?

Arcadia was built for modern EV programs—connecting schematics, harness design, and manufacturing in a single, cloud-based ECAD platform purpose-built for high-voltage systems and rapid change.

See how leading EV teams reduce errors, accelerate development, and stay compliant—start your free trial today.