Design data refers to the technical information used to bring a wire harness to life. This data encompasses every detail about the components, materials, specifications, and configurations involved in the harness assembly process: connector types, pin configurations, voltage ratings, current capacities, physical dimensions, routing instructions, and so on. Part numbers correspond to each component integrated […]

Harness-manufacturing efficiency is your goal. To get there, one avenue lies in the use of wire-harness quoting software. These specialized solutions have emerged as indispensable assets for wire-harness manufacturing. They offer a multitude of advantages, enabling businesses to streamline their operations and stay ahead in a competitive landscape. Let’s take a closer look at what […]

Why on earth should a wire harness designer understand APIs? In a nutshell, they empower you to streamline the design process, reduce errors, and optimize workflows, ultimately leading to the creation of high-quality wire harnesses. The more you know, the better. APIs – Application Programming Interfaces – are critical features in wire harness design software. […]

Think of the numerous electrical and mechanical components involved in wire harness design. Choosing the right connectors, wires, cables, terminals, and more takes more time than you might think. You have to consider factors such as voltage ratings, current capacity, form factors, environmental conditions, and compatibility with other parts when selecting from component databases. Getting […]

You might have already tried free electrical drawing software, and that’s why you’re here. Basic features offer some value, but the electrical drawing software you use determines the efficiency, reliability, accuracy, and ultimately, the success of your designs. You need something more advanced. To make your choice easier, we’ve put together 5 key factors to […]

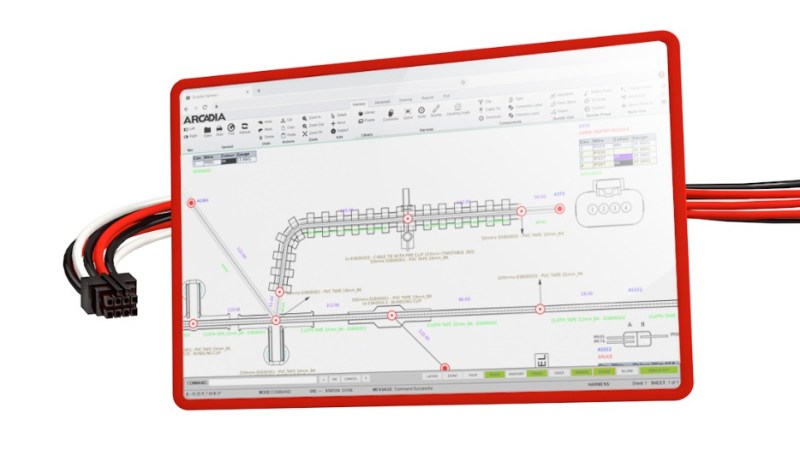

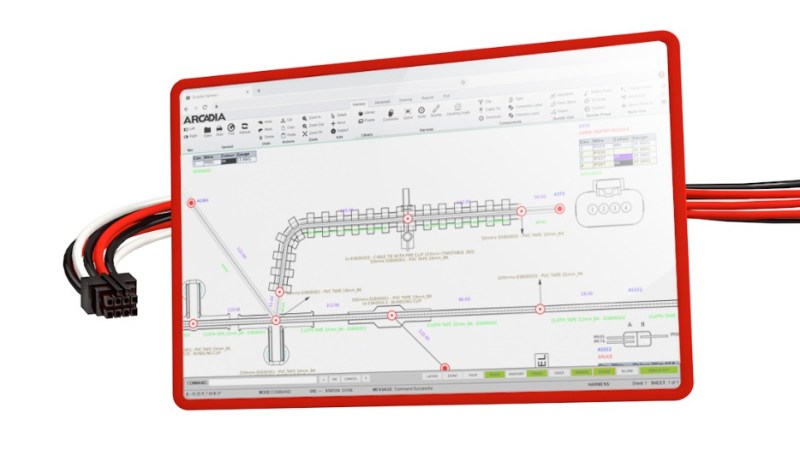

We recently conducted a Webinar on the traditional wire harness design process vs. applying the practical approach of using Arcadia. In case you missed it, check out this breakdown of what we covered in discussing what to consider when migrating to a specialized harness design suite. 1. Limitations of a Traditional Wire Harness Design Process […]

Consider exactly what wire-harness solutions are: comprehensive systems that integrate electrical wires, cables, connectors, and other components into structured assemblies. They have to provide reliable and organized means of transmitting electrical signals and power in various applications. It’s complicated, in other words. If you’re working manually, the complexity only heightens, along with the costs. Working […]

Of all the types of electrical drawings, schematic diagrams are the most helpful for troubleshooting. A wiring diagram maker can give you the relative layout of the circuit components, and you can use symbols and components. But the wiring drawing by itself isn’t particularly easy for understanding circuit operation or troubleshooting. This is where a […]

ECAD and MCAD: Which to use and how to use them together When it comes to wire harness design, there are two primary types of software: Electronic Computer-Aided Design (ECAD) and Mechanical Computer-Aided Design (MCAD). These are essentially two different approaches to designing wire harnesses. ECAD software concentrates on designing the electrical components of a […]

If you can optimize the design process for your wire harness, you’ll gain significant cost reductions across the board, including testing and validation and your harness manufacturing. Simply put, optimizing at the design phase has a knock-on effect, speeding up the harness design cycle and improving your formboard while reducing design errors and quote-to-production cycle […]